Tips for choosing a centrifugal pump

When choosing a centrifugal pump you need to take several aspects into account, whether technical or not. Context of use and other variables can, in fact, affect the choice of the most appropriate model.

Let’s take a deeper look at these factors.

Choosing a centrifugal pump: What you need to know

First things first: if you want to avoid wear and corrosion problems, you have to consider the kind of liquid you want to move. Find out what the liquid’s chemical characteristics are, including viscosity and presence of any solid particles, so you have no hesitations about the ideal pump you need and its operation.

Depending on the specific application, you will also have to consider pump sizing, in other words, the amount of liquid in the use cycle. This is an important factor in order to optimise costs.

Assessing the pump and system’s technical characteristics

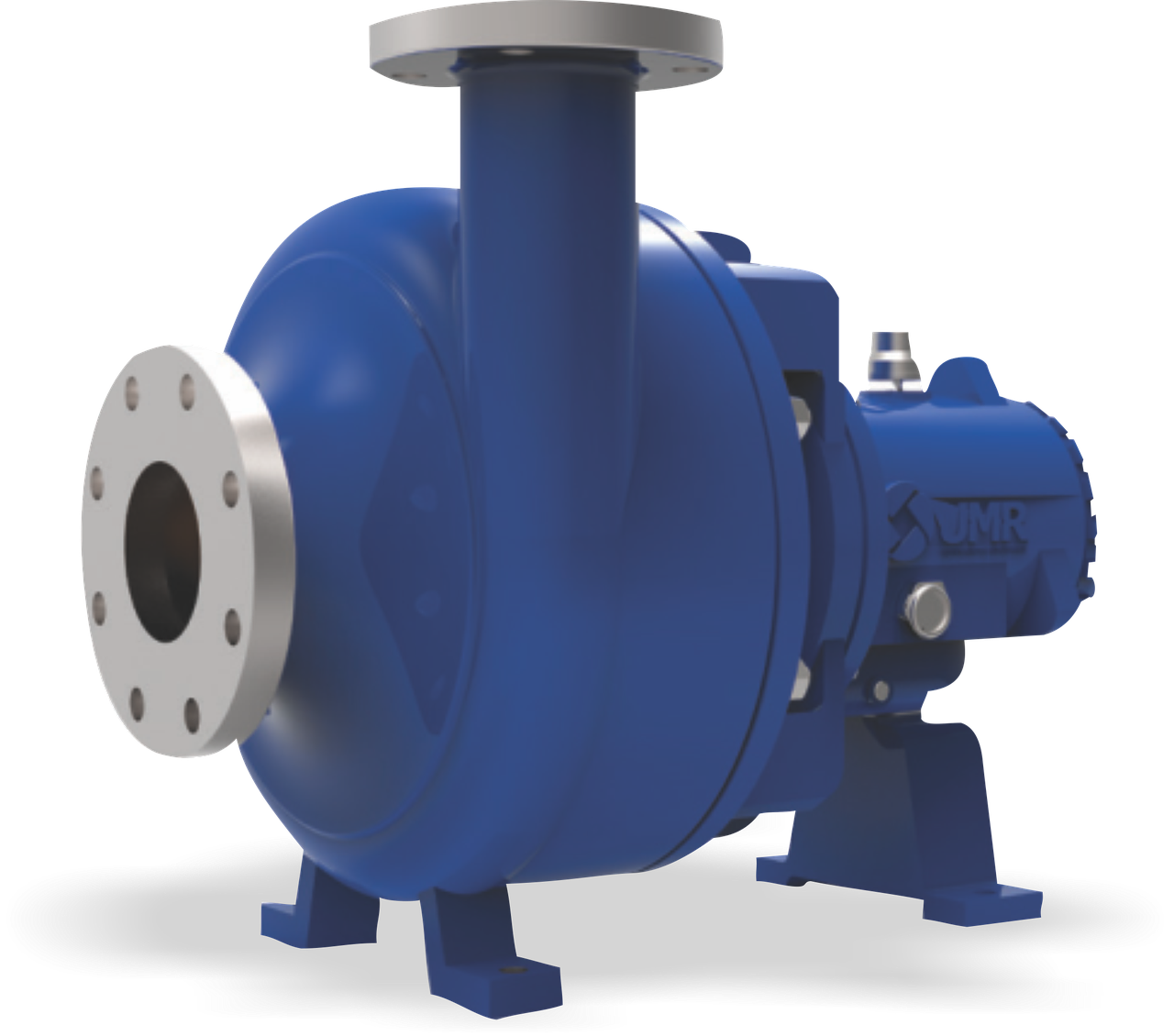

Delving deeper, a centrifugal pump is made up of fixed parts and moving gears that generate a circular motion at a certain speed. The first characteristics to look at are its flow rate and head.

Flow rate is the volume of water that moves inside the pump expressed in seconds or minutes; head is how high (maximum) the pump has to lift the liquid from the point of intake.

The system, on the other hand, is mainly made up of the pump drive motor, suction and discharge pipes, filters, valves, and the pump’s priming and drainage systems.

Pump types

From vertical pumps to horizontal pumps, these tools find application across many sectors and businesses, from industry to agriculture, through to private uses.

Let’s start with steel submersible pumps, which are widely used in industry and for irrigation. These pumps are easy to install and feature submersible motors and built-in check valve. They come in two versions:

- radial flow, for limited flow rates and high pressures;

- semi-axial flow, for high flow rates and medium pressures.

Cast iron submersible pumps are similar to these and have a great power level. They are also driven by a submersible motor and equally versatile across fields of application in terms of liquid supply.

Split case pumps are another interesting solution. With their separate chamber, they are innovative from both a technical and maintenance standpoint. In fact, since the pump casing is axially split, the rotor can be worked on without meddling with the motor or pipes.

Do you want our advice about which centrifugal pump to choose? Contact us now! We’ll be happy to help.